Why Shop Drawings Are a Must for Prefabricated Construction

Prefabricated construction, also known as prefab construction, is a modern way of building where parts of a structure are made in a factory and then brought to the construction site for final assembly.

In the fast-evolving world of construction, prefabrication has emerged as a game-changer, offering faster project timelines, reduced waste, and enhanced quality control. But while prefabrication streamlines on-site assembly, its success hinges on one critical component: shop drawings.

These detailed technical documents act as the bridge between design intent and factory fabrication, ensuring every component is manufactured to exact specifications before reaching the job site.

Without accurate shop drawings, the risk of misalignment, costly delays, and rework increases significantly.

In this blog, well explore why shop drawings are essential for prefabricated construction and how they contribute to the precision, coordination, and overall efficiency of modern building projects.

Understanding Prefabricated Construction

Prefabricated construction, also known as prefab construction, is a modern way of building where parts of a structure are made in a factory and then brought to the construction site for final assembly. Instead of building everything on-site from scratch, workers put together pre-made parts like walls, floors, roofs, or entire rooms. This method is becoming more popular because it saves time, reduces waste, and improves quality.

In a traditional construction process, workers face many challenges like weather delays, material damage, or unexpected design changes. But in prefabrication, most work is done indoors under controlled conditions. This helps keep materials safe and ensures better accuracy and consistency in each piece.

There are different types of prefab construction. Some projects use simple parts like wall panels, while others include fully built rooms or sections called modules. These modules are transported to the site and joined together like pieces of a puzzle.

One of the biggest benefits of prefabricated construction is speed. Since site preparation and module production can happen at the same time, projects finish faster. It also lowers labor costs and reduces errors that can occur on-site.

Prefab construction is used in many types of buildings, including homes, offices, schools, and hospitals. As technology continues to grow, more builders are choosing this method to save time and money while improving quality.

What Are Shop Drawings?

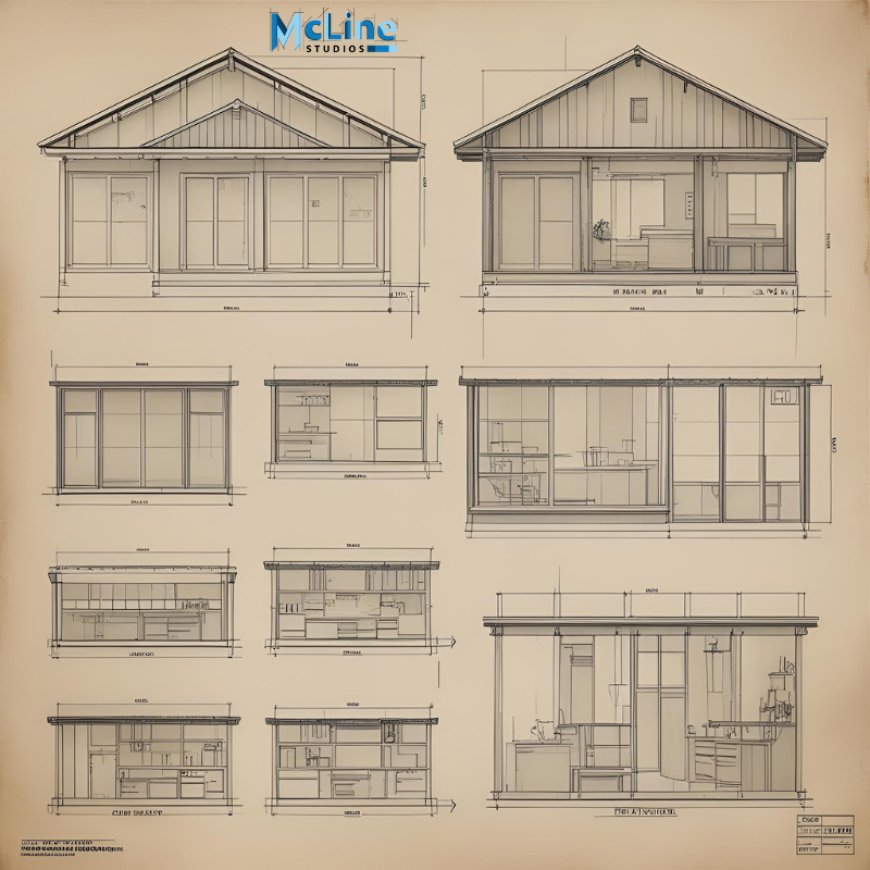

Shop drawings are detailed drawings or plans used in construction projects to show how things will be made and installed. These drawings are created by contractors, fabricators, or engineers after the main design is approved. They give specific instructions on how to build things like walls, windows, cabinets, pipes, steel frames, and other parts of a building.

While architectural drawings show the overall design and look of a building, shop drawings focus on the technical side. They include exact measurements, materials, shapes, and how different parts fit together. These details help workers, manufacturers, and installers understand exactly what to do.

For example, if a building needs custom-made kitchen cabinets, the architect will show where the cabinets go, but the shop drawings will show the exact size, type of wood, hinges, and how they will be built and installed. This ensures that everything fits perfectly on-site.

Shop drawings are important because they help avoid mistakes. They make sure that the final product matches the design and works as planned. They also help project managers check if everything is being done correctly before materials are ordered or built.

Why Shop Drawings Are Critical in Prefab Construction

In prefabricated construction, many parts of a buildinglike walls, floors, and roofsare made in a factory and then sent to the building site. To make sure everything fits and works properly, shop drawings are very important. They show the exact details of how each part should be made, assembled, and installed.

Shop drawings act like a clear instruction manual for workers and manufacturers. They include sizes, shapes, materials, and how each part connects with others. Since prefab construction depends on all parts fitting together perfectly, even a small mistake can cause big delays or cost a lot of money. Shop drawings help avoid these problems by providing correct and complete information.

For example, if a wall panel is even a few inches too big or too small, it might not fit with the floor or roof. With shop drawings, everything is checked and approved before building begins. This helps save time, reduce waste, and avoid costly changes later.

Also, in prefab construction, different teams work on different parts at the same time. Shop drawings help everyone stay on the same page, making sure there is no confusion.

Role of Digital Tools in Shop Drawing Creation

Today, digital tools play a big role in creating furniture shop drawings for construction projects. In the past, drawings were made by hand, which took a lot of time and sometimes had mistakes. Now, with the help of computers and software, shop drawings can be made faster, more accurately, and with better detail.

One of the most popular digital tools is CAD (Computer-Aided Design) software. It helps drafters create clear and precise 2D and 3D drawings. These drawings show the exact size, shape, and materials of each part. Another powerful tool is BIM (Building Information Modeling), which allows teams to create a full digital model of a building. BIM helps everyonedesigners, engineers, and builderswork together and see how all the parts fit.

These digital tools make it easy to make changes when needed. For example, if a part doesnt fit or a material changes, the drawing can be updated quickly. This saves time and reduces mistakes.

Digital shop drawings are also easy to share. Teams can send them by email or use cloud storage to access them from anywhere. This improves communication between teams and helps the project move smoothly.

The End Note

In the world of prefabricated construction, shop drawings are not just helpfulthey are absolutely essential. They serve as the link between the architects vision and the factorys production process, ensuring every component is made and assembled with precision. With detailed shop drawings, teams can avoid costly errors, reduce delays, and improve coordination among all project members.

Prefabricated construction depends heavily on accuracy and planning. Shop drawings provide that level of clarity and confidence needed to make sure every wall, floor, or module fits perfectly on-site. Thanks to digital tools like CAD and BIM, creating these drawings is now faster and more efficient than ever, allowing smoother workflows and better collaboration.

As prefabrication continues to grow, shop drawings will remain a key factor in delivering high-quality, cost-effective, and timely construction projects. They turn designs into reality, accurately, and successfully.