Industrial Adhesives Market Growth and Strategic Outlook 2025-2032

The industrial adhesives market is witnessing robust expansion driven by technological innovations and increasing applications across automotive, electronics, and construction sectors. Strategic market growth is underscored by evolving market trends that emphasize high-performance and eco-friendly adhesive solutions, impacting market shares and competitive dynamics globally.

Market Size and Overview

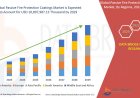

The Global Industrial Adhesives Market size is estimated to be valued at USD 47.77 Billion in 2025 and is expected to reach USD 74.72 Billion by 2032, exhibiting a compound annual growth rate (CAGR) of 6.6% from 2025 to 2032. Industrial Adhesives Market Size as trajectory reflects rising demand across diverse industrial segments requiring efficient bonding solutions. The markets expansive scope is propelled by innovations that increase product versatility and sustainability, shaping favorable market revenue and business growth profiles.

Current Event & Its Impact on Market

I. Major events along with real world use case explanation:

A. Surge in Automotive Electrification - Impact on Material Demand

- Increasing shift to electric vehicles (EVs) in North America and Europe is driving demand for lightweight and thermally stable industrial adhesives to replace mechanical fasteners, enhancing vehicle efficiency and durability.

B. Post-Pandemic Supply Chain Restructuring in Asia-Pacific

- COVID-19 aftermath forced major adhesive manufacturers in APAC, such as plants in China and India, to diversify supply chains and increase local production, mitigating future disruptions and influencing market growth strategies.

C. Global Push for Sustainability and Bio-based Adhesives

- Governments and industry players accelerate development of bio-based adhesives, reducing volatile organic compounds (VOC) emissions, creating market opportunities aligned with evolving regulatory frameworks.

II. Major events along with real world use case explanation:

A. Geopolitical Tensions Affecting Raw Material Prices

- Trade restrictions between the U.S. and China have increased costs of synthetic polymer raw materials necessary for adhesive manufacturing, restricting market revenue expansion in 2024.

B. Adoption of Industry 4.0 Technologies in Manufacturing

- Use of AI and IoT in adhesive production plants enhances operational efficiency and real-time quality control, boosting overall market dynamics and competitiveness of market companies.

C. Expansion of E-commerce Packaging Sector

- Rapid growth in global e-commerce is creating demand for high-performance adhesives in packaging, impacting market size and revenue positively through innovative bonding solutions.

Impact of Geopolitical Situation on Supply Chain

The U.S.-China trade tensions have led to tariff impositions on key raw materials such as epoxy resins and polyurethane precursors utilized in industrial adhesives. A specific case involves a major adhesive manufacturer located in Europe sourcing 30% of its raw material from China, encountering delayed shipments and increased costs since mid-2024. This disruption resulted in a 12% rise in production expenses and strained inventory replenishment cycles, compelling strategic adjustments in supplier diversification and inventory management. Consequently, this geopolitical scenario directly influenced market challenges related to supply chain stability and cost optimization.

SWOT Analysis

Strengths

- High product specialization catering to diverse industrial segments increases industry share and revenue reliability.

- Integration of eco-friendly adhesives aligns with regulatory mandates, supporting sustainable market growth.

Weaknesses

- Raw material price volatility due to geopolitical risks constrains consistent market revenue growth.

- High dependence on petroleum-based polymers limits environmental compliance among certain market segments.

Opportunities

- Expanding applications in emerging sectors like wearable electronics and aerospace offer lucrative market opportunities.

- Digital manufacturing technologies (e.g., automated adhesive dispensing) enhance product quality and reduce wastage, improving market dynamics.

Threats

- Intense competition from regional market players with lower cost structures creates pressure on pricing strategies.

- Regulatory constraints regarding VOC emissions could escalate R&D costs, affecting profitability.

Key Players

Leading market players active in the industrial adhesives market include Henkel, 3M, Bostik, Avery Dennison, H.B. Fuller, Jowat, and Pidilite Industries Limited. Throughout 2024 and 2025, these companies have pursued strategic partnerships focusing on innovation in bio-based adhesives, digital process optimization, and expansion into emerging markets. For instance, Henkels collaboration with a major automotive OEM to develop next-generation structural adhesives led to a 15% increase in its market share in the automotive segment in 2025. Similarly, 3Ms investments in AI-driven adhesive formulation processes have improved product performance consistency, setting benchmarks within industry trends.

FAQs

1. Who are the dominant players in the Industrial Adhesives market?

The industrial adhesives market is dominated by key players like Henkel, 3M, Bostik, Avery Dennison, and H.B. Fuller, among others, who lead through continuous innovation and strategic partnerships.

2. What will be the size of the Industrial Adhesives market in the coming years?

The market is projected to grow from USD 47.77 Billion in 2025 to USD 74.72 Billion by 2032, reflecting a strong CAGR of 6.6% driven by expanding industrial applications and sustainability trends.

3. Which end-user industry has the largest growth opportunity in the Industrial Adhesives market?

The automotive industry, particularly the electrification segment, offers significant growth opportunities due to demand for lightweight and thermally stable adhesive solutions.

4. How will market development trends evolve over the next five years?

Market trends will likely focus on eco-friendly adhesive formulations, integration of Industry 4.0 technologies, and diversified applications across packaging, electronics, and aerospace, enhancing market scope.

5. What is the nature of the competitive landscape and challenges in the Industrial Adhesives market?

The competitive landscape is marked by innovation-led differentiation; however, challenges include raw material supply volatility and increasing regulatory pressures, compelling market companies to optimize growth strategies.

6. What go-to-market strategies are commonly adopted in the Industrial Adhesives market?

Market players commonly adopt strategies including digital transformation, strategic alliances for technology development, regional manufacturing expansions, and portfolio diversification toward sustainable products.

Get more insights on, Industrial Adhesives Market

Get This Report in Japanese Language: ????????

Get This Report in Korean Language: ??? ??? ??

Read More Articles Related to this Industry- Industrial Applications of Vinyl Acetate Monomer

About Author:

Ravina Pandya, Content Writer, has a strong foothold in the market research industry. She specializes in writing well-researched articles from different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. (https://www.linkedin.com/in/ravina-pandya-1a3984191)