PP SHEET: A Versatile Material for Modern Industrial Needs

Introduction to PP Sheet and Its Composition

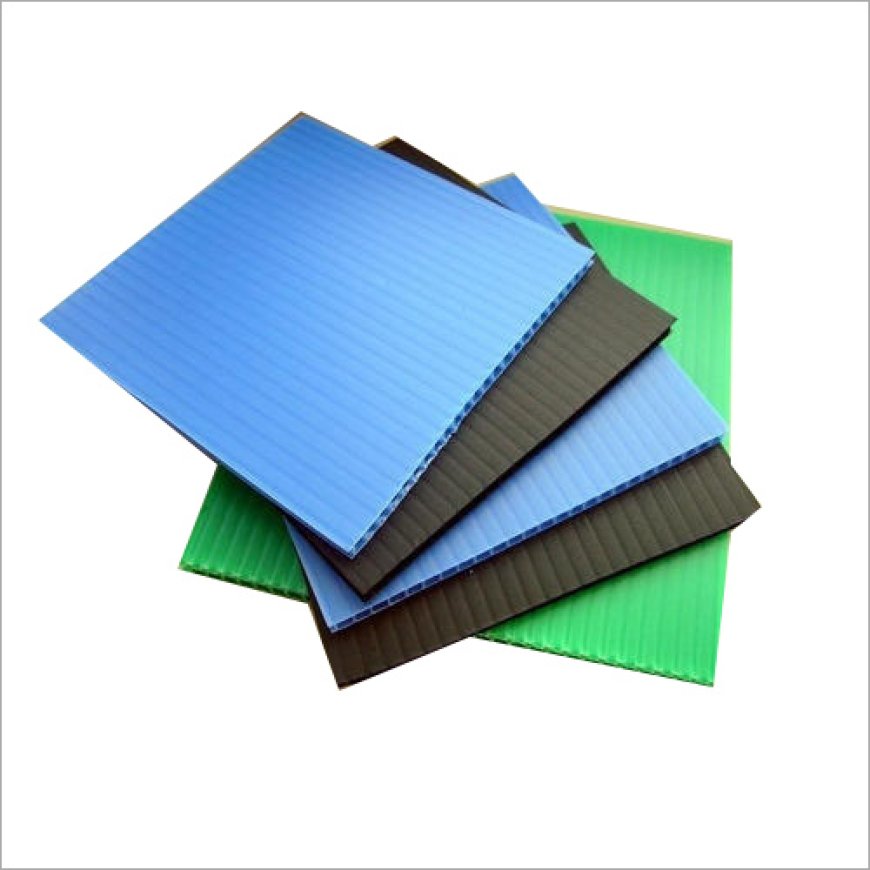

Polypropylene (PP) sheet is a thermoplastic material that is not only lightweight but also has a very high strength. PP sheet can be found in almost every industry, its involvement ranging from automotive solutions to packaging options. Best known for having excellent chemical resistance, low moisture absorption, and exceptional mechanical strength, but will also provide for injections or life cycles that measure up to between five and ten eras or usage applications in its most conventional approach. Generally accepted as reusable and flexible, PP plastic sheet is becoming more popular for commercial and residential use. On top of everything else, PP sheet is 100% recyclable, leaving you with an environmentally responsible option in the world of plastics.

Applications and Industrial Relevance

The versatility of polypropylene (PP ) sheet is one of its greatest attributes. In packaging industries, PP sheets serve as an excellent base substrate for food containers, folders, and advertising displays In the construction sector, demand for PP plastic sheet is skyrocketing because of their high impact resistance and moisture barrier potential Unlike other types of temporary floor protection or other common materials, like drop clothes or cardboard, PP sheets provide waterproofing and protection to the underlying surface during painting, remodeling and renovation The sheets not only perform well under pressure before in installation, they're incredibly easy to put down and take up - therefore saving time and labor.

Properties That Make PP Sheet Stand Out

PP plastic sheet is one of the most unique thermoplastic materials available because it combines toughness with flexibility. It is resistant to acids, alkalis, and organic solvents, therefore it can resist environments that are chemically hostile to most materials that hold up in normal settings. Due to its excellent fatigue resistance, it can flex repetitively without ever breaking - so it is the direct opposite of brittle - a key benefit for products that flex, move, or experience repetitive stress. Moreover, PP sheet has a naturally smoother surface which is often less susceptible to dirt and is very easy to clean, which is a critical requirement for both the medical and food processing environments.

PP Sheet in Floor Protection Applications

When it comes to pp floor protection sheet, this is a product that is very well accepted among contractors and builders. They deliver high coverage and protection from scratches, dust and liquid spills. The pp sheets value in large jobsites where heavy foot traffic is expected and falling objects can cause damage, makes it the most commonly used product for temporary floor covering for big construction projects, malls and exhibitions. They are waterproof and abrasion-resistant, which means if you have an expensive flooring substrate marble, hardwood or tiles, it will be protected day after day of construction work.

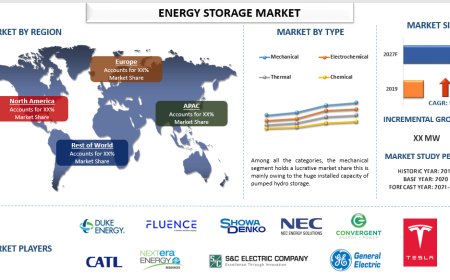

Cost Analysis and Market Dynamics

Knowing the pp sheet price is important for those industries that are buying sheets in bulk. The pp price will depend on the thickness, size, color, and if the sheet is virgin or recycled. Virgin PP floor protection sheet are generally a little more expensive since they have a purer quality of plastic with greater strength. For industries that are economically sensitive, recycled PP sheets offer a sustainable option at a lower cost. Of course, the pp sheet price is dependent on the global price of crude oil, since polypropylene is a derivative from petroleum. In India, pts manufacturers are very competitive and depending on the region, like Gujarat, manufacturers might have large manufacturing units that are running smoothly and can keep costs low, because of the scale.

Environmental Impact and Sustainability

PP sheets are sustainable as they are reusable and recyclable in line with the present sustainability purpose. Many industries use PP plastic sheet materials to reduce their carbon footprint. PP sheets limit waste generation because of their service longevity requiring less frequency of replacement. Recycling old sheets into new goods significantly reduces waste generation directed toward landfills. Additionally, while manufacturing and recycling PP certainly takes energy, it takes less energy than many other polymers, making it an environmentally and economically sensible material for mass production.

Future Scope and Innovations

As industries continue exploring advanced materials for specialized applications, innovations in PP sheet materials are gaining momentum. These materials include advanced types such as UV-stabilized sheets, flame-retardant sheets, and conductive sheets are already in the marketplace. These advancements advance the application category from a generalized space to a specialized application space, such as aerospace, automotive, electronic, or pharmaceutical industries. Manufacturers are also experimenting with custom options that allow consumers to specify color, thickness, texture, and size for their projects. As policies regarding green.

Conclusion

In conclusion, PP sheet has become a go-to product in a wide variety of industrial, commercial, and residential areas. With its chemical resistance, strength, resilience, flexibility and affordability it has made its mark in the product materials sector. Whether it is potential use as a pp floor protection sheet on a site or a PP roofing sheets for a high-gloss signage board, products made from pp plastic sheet provide numerous possibilities for use in both practical and imaginative realms. As demand continues for eco-responsible, as well as high-performance products, pp sheet will, no doubt, drive the polymer-based products of the future.

Frequently Asked Questions (FAQs)

Q1: Who is the largest manufacturer of PP SHEET?

Singhal Industries Pvt. Ltd. has been known as one of the biggest and reputable manufacturers of PP (polypropylene) Sheets in India. Singhal Industries is a company based in Gujarat that is well known for providing PP sheets across varying industries such as packaging, automotive, construction, industrial, and agriculture.

Q2: Where can I use PP plastic sheets?

A: PP plastic sheets are applicable for use in packaging, automotive interiors, medical equipment, construction floor protection, and display signs, as they have great strength and are resistant to chemicals.

Q3: Are pp floor protection sheets reusable?

A: Yes, most PP floor protection sheets are reusable, durable and will last through many projects, making them economical and eco-friendly.