Top Challenges In Embroidery Digitizing And How Services Solve Them

If you've ever tried to digitize a logo for embroidery, you’ve probably hit more than a few bumps. Some designs don’t stitch out the way you expected.

If you've ever tried to digitize a logo for embroidery, youve probably hit more than a few bumps. Some designs dont stitch out the way you expected. Other times, the thread breaks every few minutes. And dont even get started on getting text to look clean.

There are real challenges that pop up in embroidery digitizing, especially when you're aiming for professional results. The good news? Reliable embroidery digitizing services are built around solving these exact problems.

Why Is Embroidery Digitizing Tricky In The First Place?

Embroidery machines aren't smart on their own. They need a digital file that tells them what to dowhere to stitch, how to layer threads, what direction to go, and more. That file is called a digitized design.

Even the best software wont save you from a poor setup. Every design brings its own issuessmall text, lots of colors, weird shapes, and different fabric types.

And each one can mess up the final result.

Main Challenges In Embroidery Digitizing

Lets walk through the common hurdles.

1. Small Text And Fine Details Get Lost

Tiny fonts look sharp on a screen but blur in stitches. If the text is too thin or too small, it ends up looking like a blob on the fabric.

Services handle this by adjusting letter spacing, stitch density, and thread paths. Sometimes, they even redraw text to make it clearer.

2. Poor Stitch Pathing Wastes Time And Thread

When a design has too many jumps or overlapping stitches, the machine slows down, and the thread can break.

Good digitizing plans out clean paths that the machine can follow smoothly. Fewer jumps = faster runs.

3. Not Every Fabric Works The Same

Something that looks great on denim might pull or bunch on a stretchy T-shirt.

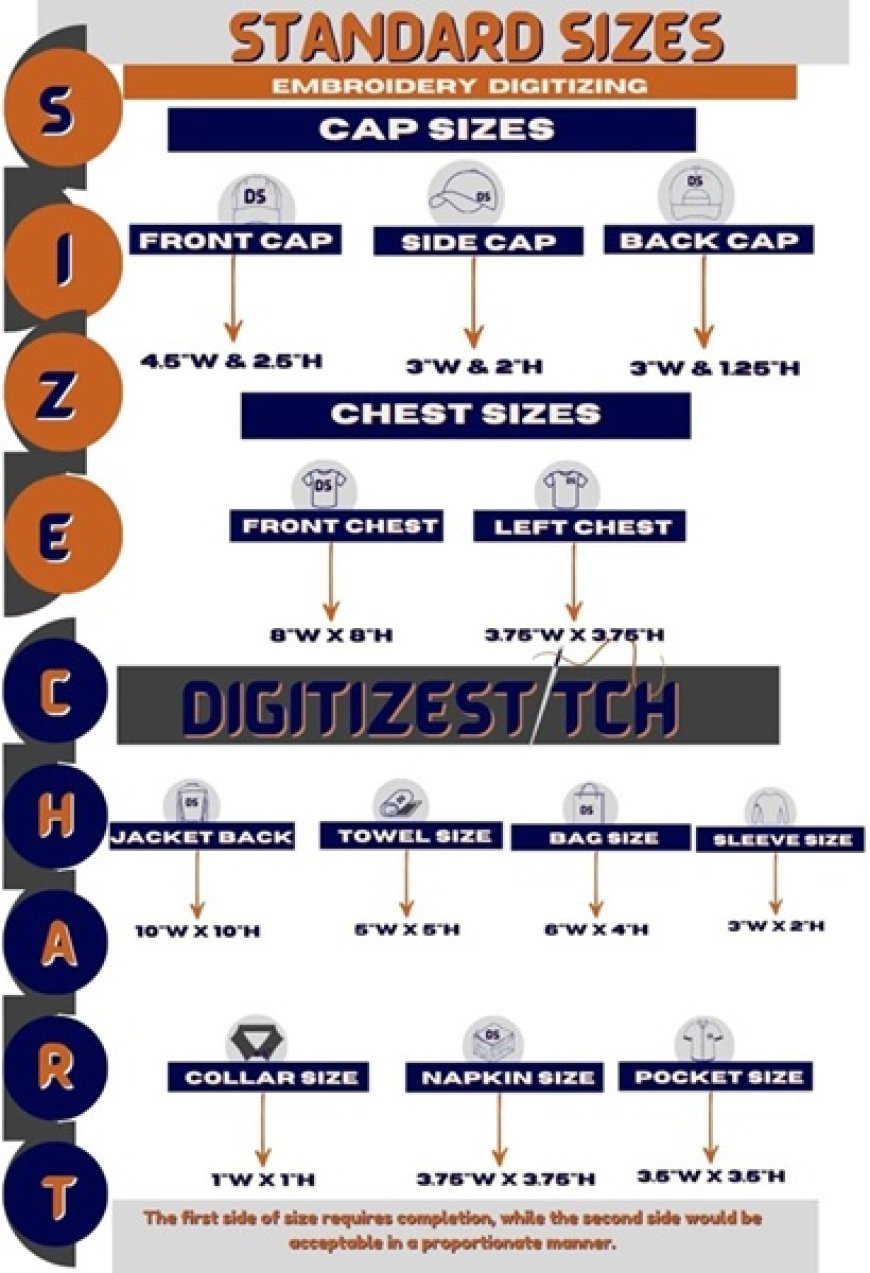

This is where an embroidery size chart becomes handy. It helps decide the right size for the fabric type. A professional will also tweak the underlay and density based on what youre stitching on.

4. 3D Puff Designs Need Special Attention

3D puff embroidery is cool, but its way more complicated than flat stitching. You have to plan the design for foam. That means the top stitches must cut the foam just righttoo weak, and it falls apart. Too strong, and the design looks smashed.

Only skilled digitizers can create a puff design that holds its shape and looks clean. Its a balancing act.

5. File Format Confusion

You might design something in PNG or JPG, but embroidery machines dont read those. They need stitch files like DST, PES, EXP, and others. And converting isnt automaticit has to be digitized properly.

Thats why just uploading an image to a machine doesnt work.

6. Uneven Or Misaligned Stitching

Bad digitizing leads to uneven fill areas, misaligned outlines, or gaps in the stitching. It can ruin an otherwise great design.

Professionals know how to fix this by adjusting stitch angles, underlays, and pull compensation.

Common Issues (And How Services Fix Them)

Heres a table that sums up what can go wrongand how services help:

|

Challenge

|

Problem You See

|

How Services Solve It

|

|

Small text

|

Letters look messy or unreadable

|

Adjust letter spacing and stitch density

|

|

Bad stitch pathing

|

Slower run time, thread breaks

|

Clean path planning and fewer jumps

|

|

Wrong size for fabric

|

Design bunches or looks stretched

|

Use of embroidery size chart and adjustments

|

|

Poor 3D puff setup

|

Foam leaks, design loses shape

|

Special digitizing for 3D puff embroidery

|

|

Image file confusion

|

Cant upload JPG/PNG to machine

|

Convert artwork with proper digitizing

|

|

Misaligned outlines

|

Gaps and overlaps in final stitch-out

|

Adjust pull compensation and underlay

|

How Embroidery Digitizing Services Help

1. They Know What Works (And What Doesnt)

Most services have worked on hundreds, even thousands, of logos. They already know what kind of fonts or shapes dont stitch well. Instead of guessing, youre working with someone who already has a fix ready.

Whether its a basic logo or custom embroidered patches, theyll know whats doable.

2. They Test And Tweak The File

You get a file thats already tested. Thats a big deal. A test run might reveal that some parts pull or dont sit right. A good digitizer adjusts it before sending you the final version.

This is key for things like digitizing logos for embroidery, where clean results matter a lot.

3. They Match The File To Your Machine

Different machines read different file formats. A pro will give you the file type you need, already set up with the right settings.

No guesswork. Just load and go.

4. They Save You Time

Doing it yourself? It could take hoursplus rework if it goes wrong. Outsourcing to embroidery digitizing services USA gets you pro-level work fast.

When To Use Custom Embroidered Patches Instead

Sometimes the problem isnt just in the digitizing. It's the fabric.

For hats, bags, or jackets where direct embroidery is tough, custom embroidered patches can save the day. These are stitched on a patch first, then added to the item later.

It makes tricky materials easier to work with. Also, theyre reusable and look really clean.

If youve had trouble with direct embroidery, switching to patches might be a better solution.

Real Talk: What Happens If You Skip Good Digitizing?

Lets say you ignore this stuff. Maybe you use free software or a cheap auto-digitizer online.

Heres what can happen:

The design doesnt stitch at all

Text becomes unreadable

The outline is way off

You waste fabric and time

Clients arent happy

Even if you save money upfront, you end up paying more in the long run. Thats where working with pros makes a difference. Whether its 3D puff embroidery, a school badge, or custom embroidered patches, they make sure it runs clean the first time.

Questions You Should Ask A Digitizing Service

Before you send your design off to be digitized, here are a few quick things to ask:

Can they provide a test stitch-out?

Do they offer edits if needed?

What file formats do they support?

Have they worked with your fabric type before?

Can they handle 3D puff embroidery or small text?

Getting clear answers upfront can save you trouble later.