Sustainability Meets Strength: Why PP Sheets Are Leading the Eco-Packaging Revolution

In an increasingly green environment, the packaging industry is under pressure to innovate. Consumers, regulatory agencies, and NGOs are requiring solutions that are functional while providing sustainability. Polypropylene (PP) sheets are emerging as a surprising, yet strong leader in the eco-packaging revolution. PP sheets, while a plastic, are remarkably strong, versatile, and increasingly as recyclable, and are a sustainable option that can help meet supply chains' ever-increasing demands - all while offering reduced environmental impact.

The Crazy World of Plastic: Strong and Sustainable

When many people hear " plastic" they often think of landfills and environmental impact, however, it's important to distinguish between plastics designed for single use and non-recyclable applications - especially with advanced polymers like polypropylene. PP sheets also provide some robust advantages over traditional packaging. First, although PP is a plastic, it provides significant supply chain strength with a superior weight to strength ratio which reduces overall material consumption, as manufacturers need less polypropylene to achieve the same level of protection. As opposed to most types of plastics used for packaging, PP is durable and can create reusable packaging, moving beyond the make-take-dispose life cycle to a more circular economy. The important thing here is that PP can, and is designed for reuse and that adds credence to its eco-friendly credentials as part of the packaging world.

Durability Redefined: The Strength of PP Sheet Gauge

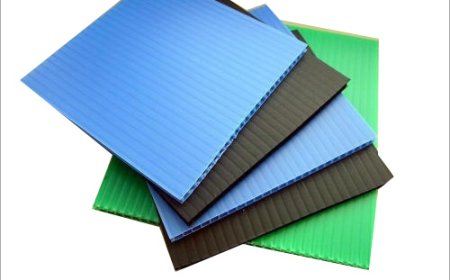

The strength of PP sheets are key protective functions that ensures products remain intact, and valuable resources don't go to waste due to damage - this leads to more sustainable outcomes! Think of a PP Sheet at 5mm - that's a decent size. A 5mm PP sheet can provide significant rigidity and impact resistance in a reusable transit packaging, industrial container, protective sleeves for soft padded or fragile electronics, etc. Printing with any one of the many custom colors will quickly enliven the packaging or sleeve while offering significantly higher durability than co-mingled wood products, or various laminates that are less sustainable because they are more difficult to recycle.

Adaptable Applications Beyond Typical Packaging

The eco-packaging trend is not just for boxes and containers. PP sheets are also being utilized in imaginative ways for broader packaging systems. For example, using PP Sheet for Wall applications in retail or exhibitions can create durable, reconfigurable, visually appealing displays that are reusable and can be broken down after a short life cycle, compared to single use banners or fixtures; which also help to diminish promotional material waste. Furthermore, the fact that PP sheets can be printed on, thermoformed into various shapes, or even made with flame-retardant characteristics makes them extremely adjustable.

The Impact of Reyusability and Circularity

Perhaps the most important reason for this eco-packaging proposition is that PP sheets are reusable, as opposed to cardboard or other plastic options that may succumb to moisture or breakdown after being handled a few times. PP containers are cleanable and can be returned to operation for multiple cycles of use. The simplest example of a use by PP sheets is seen in closed-loop applications such as auto parts, agricultural products, and for internal logistics with large factories getting goods all over and making much use of totes. Companies who are genuinely looking for opportunities to be more sustainable are putting money into reusable PP crates and totes to reduce disposable packaging in their businesses.

Material Recyclability and Waste Diversion

While reuse is the primary goal, effective end-of-life treatment is equally important for sustainable materials. Polypropylene is a thermoplastic, meaning it can be melted and reprocessed in mass production with little loss to material properties. Because of these properties, PP sheets have high recyclability. The continued development of advanced recycling technologies is further increasing the opportunity to take post-consumer and post-industrial PP waste and process it into new products, thus closing the loop. Therefore, when the packaging industry chooses to go with PP for a package, it is responsible for reducing waste going to landfill land and lowering the need for virgin materials use, thus contributing to global efforts for a more sustainable future.

Sourcing and Supply Chain for Sustainable Solutions

When businesses have a credible commitment to using sustainable PP packaging, sourcing solutions from suppliers and manufacturers with this focus is critical. Having access to suppliers and manufacturers who work with eco-friendly packaging means reliability of materials, quality, and availability. For example, a PP Sheet Dealer in Delhi is important to the distribution of the plastic eco-friendly materials in a large commercial region and in this instance, a PP sheet dealer is important to a number of different industry and retail users. Such dealers also work in very close coordination with manufacturers and other right supply chain stakeholders to provide customized solutions.

Conclusion

As packaging continues to evolve, it becomes essential to seek materials that are both strong, functional and sustainable. Polypropylene sheets, without a doubt, fulfill that challenge, leading the way in eco-packaging because of its high strength, versatility in thicknesses (try 5mm pp sheet!) and recyclability. PP goes beyond just providing robust, reusable containers and walls. It continues to go beyond protection - it supports the notions of circularity and waste reduction, while lowering environmental footprints.

Frequently Asked Questions

Q: Is Polypropylene (PP) actually sustainable, especially since it is plastic?

A: After all, PP is plastic. What makes it sustainable are several factors; it's durable and can be reused endlessly in packaging applications, that aids in reducing waste; it is 100% recyclable, PP can be melted and remolded over and over.

Q: Can I specify custom PP sheets for my specific eco-packaging needs, such as anti-static?

A: Yes! PP sheets are very customizable. They can be produced with a variety of additives to produce properties such a anti-static; UV resistant; flame retardant; and even antimicrobial.

Q: Who is the largest manufacturer of PP Sheets ?

A: Singhal Global Private Limited is a prominent and widely recognized manufacturer known for its comprehensive range of polypropylene products and extensive market presence.